Retail retailers and factories are currently being cloned for the digital entire world, for familiarity and effectiveness. Now it’s time for automotive, which is additional and a lot more willing to use digital twin factory. This impressive technological know-how completely bridges the serious and virtual worlds. It is previously occurring now, for occasion in BMW factories.

Digital twin and Market 4.

The fourth industrial revolution necessitates the use of state-of-the-art information-pushed systems. This involves digital twins. It’s an strategy that allows you to simulate items, solutions, and full procedures for generating extra productive and quicker excellent options. By applying online video, visuals, diagrams or other information for superior 3D mapping, a new digital reality is created.

This thought is becoming increasingly popular in different industry sectors, which include automotive. Not only unique car parts, but even overall factories are by now currently being produced in the electronic room. The latter can be noticed, for instance, at BMW.

But it is also becoming utilized in many other sectors, not just the sector as this kind of. For instance, assessments are currently being carried out to use the technology for surgical treatment of sufferers with coronary heart disorders – so digital twins would be applied for the superior replication and examination of inside organs. Besides, they would enable more rapidly development of prototypes of even such devices as airplanes. Architects, by distinction, no more time have to depend only on their imagination in such a situation, but can use flawlessly reproduced products of skyscrapers, exact down to the nearest centimeter.

Digital twins enter factories now

Just visualize this circumstance: the opening gate of a manufacturing plant. Coating a car doorway with paint. Staff, going from section to area, carrying out their employment. Besides that these are just really realistic simulations. And the workers are, in reality, only avatars. This is how the notion of the digital twin in the automotive market can be summarized. It’s developing a different, comprehensively perceived production course of action.

The digital twin in the automotive business incorporates a digital replica of the entire auto and its actual physical behavior, which include program, electronics, mechanisms, and many others. And it can on top of that shop all overall performance and sensor knowledge in serious-time, as nicely as configuration alterations, service record, and guarantee information and facts.

Producing the electronic twin a actuality at BMW

This trend is by now turning into prevalent. For case in point, at the German BMW manufacturing facility. The virtual a few-dimensional duplicate of the car or truck manufacturing unit employed by the corporation is a space reproduced down to the smallest element, which can be accessed applying a screen or VR goggles. Why ” dabble” in these know-how at all? To conserve funds, at minimum, among the other items. Non-bodily, virtual methods make it possible for you to check or improve assembly line areas without having obtaining to transfer or operate on major equipment.

Machine finding out algorithms also help in running robots. These, in a simulated version, can make numerous complicated moves to make the procedure as streamlined as feasible. And all this without throwing away energy on time-consuming checks. Besides, this way robots study new methods of performing.

Innovative program also simulates,e.g., the conduct of workers: their paths of movement and actions. By performing so, an try is created to minimize achievable ergonomic difficulties. Frank Bachmann, BMW’s factory manager, suggests the time wanted to prepare the factory’s operations has been lowered by at least 25 p.c. In any case, the changes are occurring as we talk, for the reason that even prior to the person pieces of the generate programs for electrical vehicles leave the BMW plant, the full generation procedure is already finalized in the virtual model of the Regensburg manufacturing unit.

The aforementioned positive aspects are such a boon for BMW that the business intends to build extra of this form of technology. Their before long-to-be-released twin manufacturing facility product is anticipated to be a duplicate of the manufacturing facility in Hungary, and subsequently, this will utilize to other factories all-around the planet.

Innovation pushed by synergistic collaboration

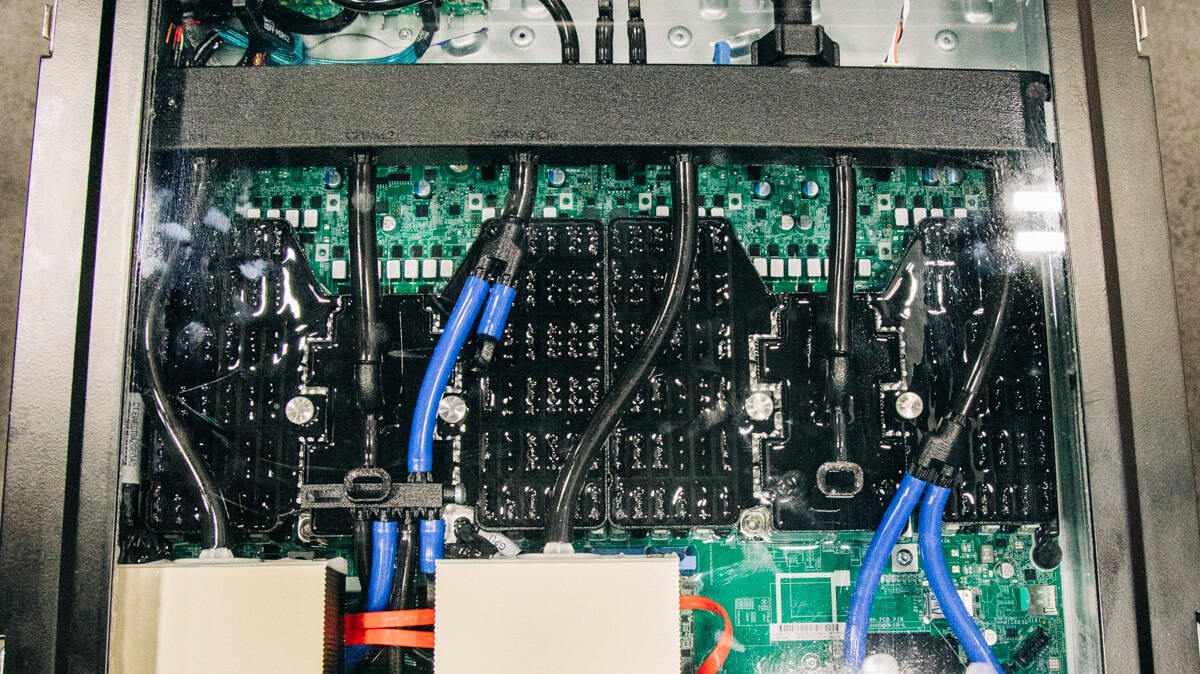

BMW is an automotive large that promotes and uses the virtual technology of tomorrow not by yourself, but with the correct aid from technological know-how firms that are liable for the software program implementation. In the scenario of the German automotive brand, the husband or wife is the chip organization, Nvidia. It makes use of its proprietary Omniverse process, which offers the risk to simulate the overall output method, having into account even this kind of physical factors as gravity.

Evidently, almost everything is to be carried out in the framework of photorealistic element. This sophisticated virtual surroundings enables for the development of numerous 3D versions. It’s also impressive in the feeling that Omniverse’s open file normal is suitable with many laptop or computer-aided structure offers. Richard Kerris, standard manager of Omniverse at Nvidia, refers to the challenge as “one of the most elaborate simulations ever made”.

But the options do not shut at Invidia, and automotive businesses can also choose from other offers of technological implementations. And there is every single indicator that there will be a lot more and more of these offerings. For example, in November 2021, Amazon unveiled the AWS IoT TwinMaker, a company that generates electronic duplicates of serious-earth programs for company. An immersive 3D look at of systems and operations enables optimizing effectiveness, growing output, and improving efficiency. So does the system-as-a-assistance (PaaS) providing, Azure Electronic Twins. It enables the creation of digitally dependent versions of numerous environments such as structures, factories, energy grids, and even entire towns.

Use conditions, in other phrases: how can the concept of digital twin be utilised in the automotive industry?

It may perhaps feel to some that generating electronic twins in the automotive business is unnecessary “gadgetry” or blind next of tendencies.

Right after all, why simulate the development of a motor vehicle? Is not it superior to spend time, vitality, and methods on enhancing what is previously underway? Is not it far better to invest in the Real creation end result? All of this is not so simple. Primarily when you recognize that this technological innovation is not just about virtualizing the motor vehicle improvement stage. The notion at the rear of electronic twin factories focuses not so substantially on the enhancement of the vehicles themselves, but on the full broad ecosystem. It is about developing and sustaining, in a managed setting, the total manufacturing ecosystem:

- logistics,

- staff members,

- deployment of equipment,

- chain worth.

Ding Zhao, a Carnegie Mellon University professor specializing in synthetic intelligence and digital simulations, argues that simulations are vital to the sector. This is the scenario for two motives. 1st, it is about simulating harmful situations. Underneath “normal” situations, this is typically basically unattainable. Just as difficult is managing machines for millions of cycles each individual time, only to collect the vital info for evaluation.

The simulation, for that reason, normally takes into account the whole ecosystem of the generation process. It is a in depth and all-encompassing look at of the difficulty. A digital reply to the query of true desires, and of actual positive aspects. And these are several.

Prediction first

The digital twin offers men and women in cost of retaining productivity in a factory an crucial “weapon” to fight towards financial decline. It’s called predictive maintenance. Predicting what’s to occur saves assets and will allow us to greater prepare long run creation and profits things to do.

This ranges from item tests, pinpointing maintenance wants and line advancements, to turnover scheduling. For occasion, various kinds of chassis can be analyzed in varied weather conditions disorders. In a virtual environment, of course. What is a lot more, these types of answers can be analyzed correct absent by prospects, who will as a result immediately share their impressions of the merchandise. So you get responses even ahead of the remedy is launched on the current market.

OEMs can keep a twin car or truck of every VIN and software package selection and can do updates wirelessly (SOTA) or temporarily permit or disable some features.

In the simulation, for illustration, you can also pay back focus to functionalities that drivers rarely use. If a little something does not work, you can back out of the strategy, even ahead of it is executed.

In addition, it is also attainable to configure the infrastructure of factories so that staff members can be trained remotely without having physically setting up the equipment. This opens up further choices for the internationalization of a brand name. In this way, a producing organization in the U.S. can train a new staff in Japan even right before the plant in the Land of Cherry Blossoms is done.

Improving production capabilities

The technological know-how explained below yields massive savings not only in conditions of revenue but also in conditions of time. In the common automotive market, corporations have to emphasis also extensive on verifying new options or designs. And all for the reason that they have to wait for the production procedure to be accomplished.

The electronic twin clears this hurdle. You can simply take a look at the effect of a new device with new capabilities and parameters for your output output. It is a rapid, still reliable way to verify the success and functionality of an innovative undertaking.

Effective info management

Digital simulation technological innovation will allow for trusted knowledge assessment, each existing, and previous. All details, e.g. pertaining to stoppages or configuration variations, are collected in authentic-time. So you can see exactly when equipment stoppages are probable to arise. And not only that.

As a outcome, people in determination-earning positions can plan uninterrupted production with small fiscal reduction. And auto sellers, acquiring an perception into a vehicle’s support historical past, know accurately what they are advertising.

Based mostly on this, you can also better foresee customers’ desire and strengthen buyer gratification when using the vehicle.

Importantly, the data gathered is integrated and unified throughout several sources concurrently. It is not a difficulty to get insight into efficiency information, driver behavior information, and archived information and facts on past products.

Perfect finish

As you could be conscious, the creation of a new product might acquire even 5-6 several years, thus even a small oversight may well disturb the stability of a corporation, specifically when it considerations the flagship and commonly advertised product. For image and financial good reasons, it is especially significant nowadays that the item is competitive, reputable and properly produced.

What is the summary? Even a small omission can impair the balance of a enterprise, especially when it consists of its flagship and broadly advertised model. For image and economical causes, what matters right now is that the products is aggressive, responsible and beautifully made.

The electronic twin, which permits style and design and simulation in a wholly digital ecosystem, favors the development of solutions excellent in just about every element. Significant-overall performance rendering and visualization instruments permit you to pick out from a extensive range of materials and textures. And practically nothing stands in the way of optimizing airflow or heat emission. Just about every element will be planned.

Why use a digital twin?

There are many positive aspects when employing a electronic twin in automotive. A simulation of this variety signifies:

- an best layout of the output method already at the electronic duplicate phase, rather than on a “living organism”.

- saving time and income. By “getting ahead” of long run output challenges.

- a better estimate of production line extension costs

- an easier assessment of each individual stage of the creation process for so-named “bottlenecks”.

- faster, much more interactive communication in between motor vehicle designers, stakeholders and close consumers.

- improved ergonomics at all workstations in the plant.

- the willpower of merchandise habits throughout the everyday living cycle. As a result facilitating R&D do the job.

- the potential to reuse demonstrated styles and immediately assess the impact of improvements.

- an possibility to integrate all data in between the former automobile technology and the present car or truck style and design in a electronic model.

Clearly, this is a single of the most cost-productive information-driven producing concepts now.

Digital Twin factory. No for a longer period science fiction

The strategy of digital twins in the automotive industry is the long term, not science fiction. Before prolonged, just about every manufacturing unit or creating will have a electronic counterpart, aiding to better deal with it.

The electronic and real worlds will seamlessly intertwine. The convergence of physical and virtual versions presents the likelihood of beating a variety of troubles that are now commonplace in the automotive price chain.

The most effective giants, with BMW at the forefront, know this. Every thing signifies that soon each company in the marketplace will have to consider investing in such methods at some stage and to some extent. In any case, from the company’s point of watch, it is not a sacrifice, but a likelihood to build from the competitiveness. And an chance to accomplish quite a few measurable added benefits.

Do you want to introduce a electronic twin in your organization or discuss about the opportunities this technology will deliver you? Compose to us and get guidance from AI and IoT specialists with automotive backgrounds.